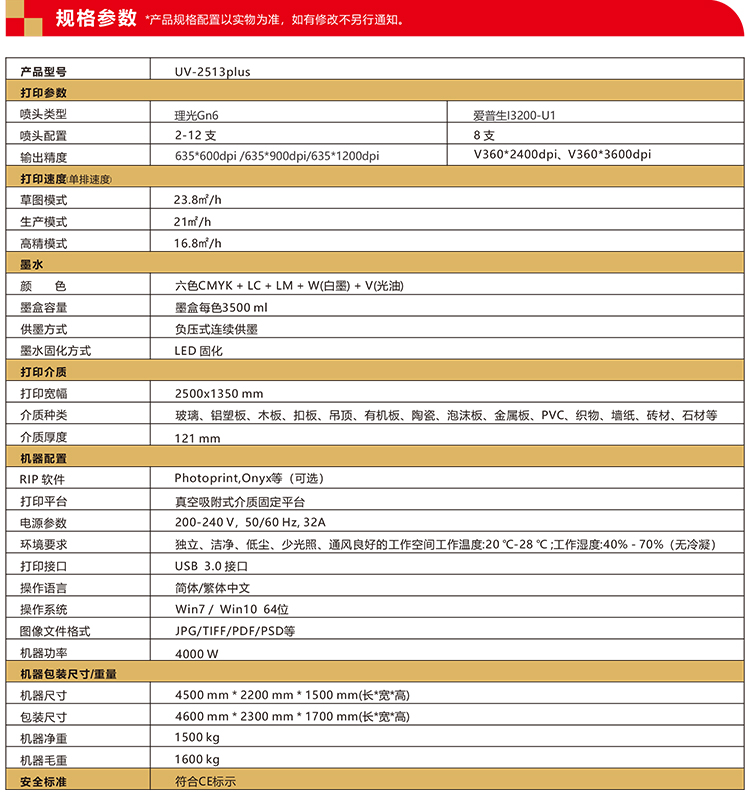

UV平板打印机Locor2513(Gen5)理光喷头

LED-UV平台式喷墨打印机

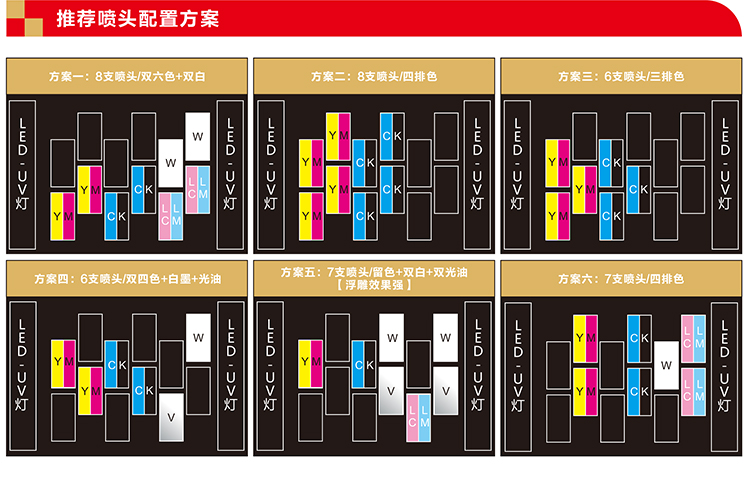

【理光Gen5/Gen6喷头 2-12支喷头】

喷头介绍

1. 理光喷头是一款工业级喷头,在UV打印下精度和速度方面都有很好的表现,满足客 户的要求;

2. 具备白彩+光油同出打印功能,浮雕、光油效果一次打印完成,成像逼真,且不易堵头;

3. 理光Gen6喷孔:5PL;理光Gen5喷孔:7pl;理光Gen6的打印精度更高,灰度渐变更加自然,画质更好;

4. 理光Gen6喷头在Gen5的基础上,速度提升40%,快速提高平板机的打印速度。

多种成像模式

1. 多层成像:全彩、彩白、彩白彩、彩白光油。

2. 多层成像功能可以在承印材料上快速在现浮雕及其它3D的图像效果,雕刻感、触手可及的凹凸感。

3. 这项功能可以用最适合的打印模式将每一处进行独立设定,不仅有助于提高产能,还能保持最佳品质输出每一份活件。

先进技术确保连续打印出丰富多彩的画面

1. 高品质机架-机器整体采用钢架结构加淬火处理(平台调节点多达32个,四排八列)平台整体平整精度(10丝以内);采用欧美结合设计,并进行高温退火处理,保证机架更稳定、不变形。

2. 传动系统 确保机器稳定打印:1.X轴采用双直线导轨传动,保证小车打印更加稳定;

2.Y轴采用的是直线导轨+丝杠双传动控制系统,保证小车在Y轴运动状态的稳定性,也保证了。

3. 抽真空装置:抽真空装置降打印平台分成4个区域,每个区域可独立呈现在显示屏上,并有单独的按键;操作人可根据承印材料的尺寸和种类对吸附强度及真空区域的位置进行控制,确保打印生产一致性。

4. 智能断电续打系统:机器操作控制中配备有断电续打系统,若遇到停电再次来电后,机器无缝拼接,继续打印未完成的画面,智能省事省心!

5. 静电消除器:喷头两侧的UV灯上部安装有专业的静电消除器,有效避免静电对喷头打印中的干扰,提高机器打印效果和打印精度。

市场应用介绍:

UV平板机应用介质广泛,在亚克力、PVC板、玻璃、铝塑板、木板、扣板、吊顶、有机板、陶瓷、波纹板、泡沫板、金属板、塑料、织物、墙纸、砖、石等介质上均可实现精美画质打印。

- 上一篇:暂无信息

- 下一篇: 乐彩磁悬浮UV平板打印机理光G6喷头2513plus