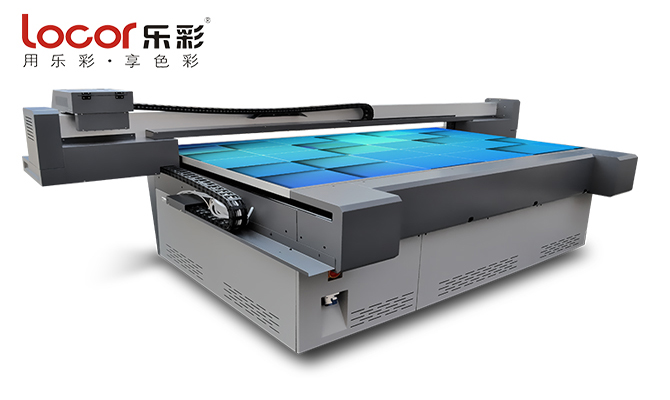

UV平板打印机前景如何

随着社会的进步和人们生活水平日益提升,UV平板打印机凭借其独特的科技优势被广泛认可。目前UV平板打印机不仅仅用来打印户外广告牌,而是更多地深入到家具印花、建材加工、艺术品仿制、硬性包装盒等众多领域。

UV平板打印技术之所以被大众市场认可,最初原因是其优秀的白色打印品质和耐紫外线打印工艺,打印的画面颜色逼真、色彩鲜艳、耐候性极强。此外,用UV平板打印机打印大部分常规板材,不用覆膜、涂层处理,不仅精简了制作工序,间接上也降低了生产成本。

其实,当代采用UV平板打印工艺制作个性化产品,其最大优势在于个性化定制简便、即打即干方面。只有这样大家才有更多的精力投入“如何把控瞬息万变的个性化市场需求,以及以更快的速度抢得订单”方面,对于中小企业来讲持续获得优质订单才是生存之道。

此外,对于UV平板打印工艺能被大家广泛认可,另外重要的一方面是它支持打印范围很广泛,不挑打印材质,而且打印效果甚至比以往丝印、移印工艺更好。而数码UV平板打印工艺也正在往细分化领域发展,比如有专门的陶瓷打印工艺、专用玻璃打印工艺、水晶浮雕打印工艺等等。

- 上一篇: uv平板打印机可以打印哪些材料

- 下一篇: 旗帜机日常操作需注意事项