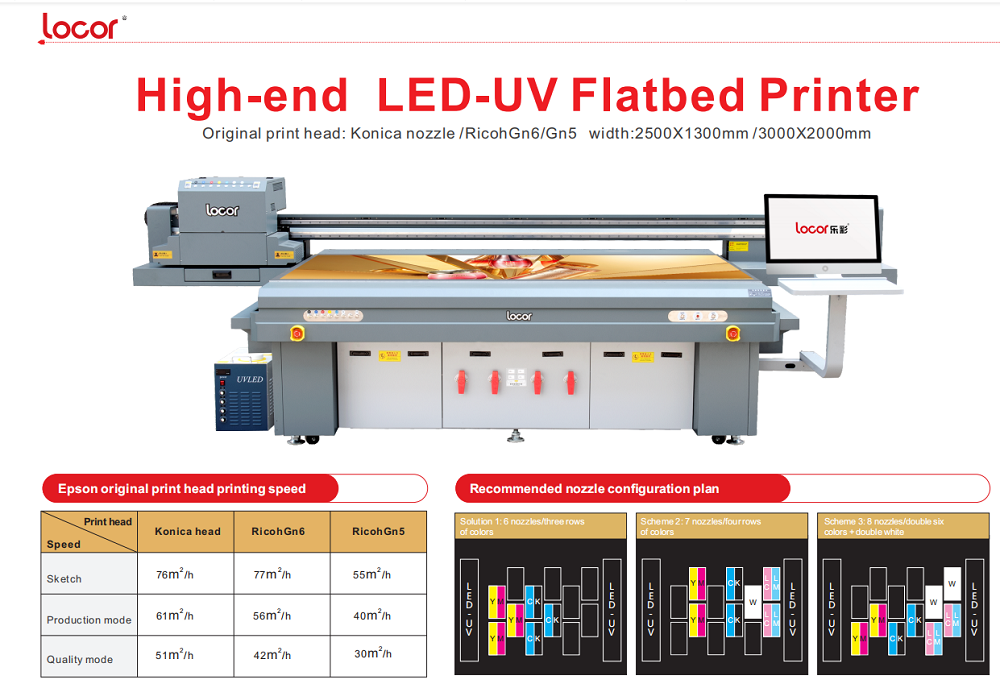

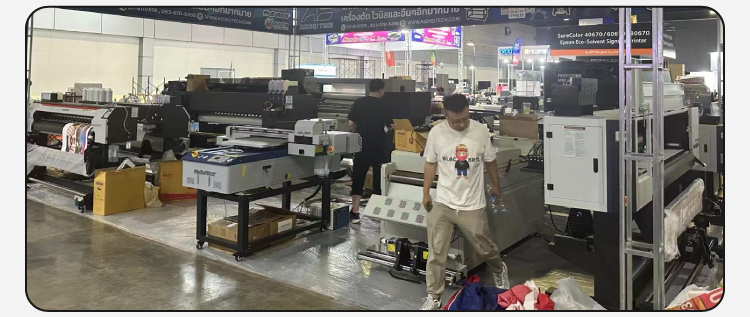

UV-2513 UV Flatbed Printer with industrial Ricoh Gen5 print heads

1. The positioning device realizes vertical printing and repeated printing;

2. The leakproof design protects the operator from ultraviolet light pollution;

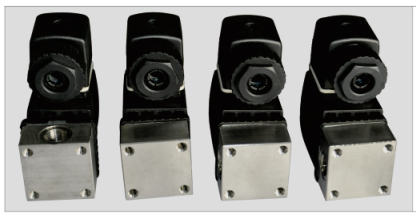

3. The device which can cut off the negative pressure stop stop valve, not dirty hand to stop head;

4. Automatic detection of material thickness, high efficiency of double zero printing, convenient cavity adsorption control;

5. Color control in line with international standards, curve and density adjustment function;

6. It has all the advantages of a flatbed printing machine and is compatible with the powerful function of roll to roll;

7. Anti - static design to reduce printing head fly ink phenomenon.

| Product Specification | ||||||||

| Model | UV-2513 | |||||||

| Printhead | Ricoh GEN5 | |||||||

| Heads Number | 2-8 | |||||||

| Resolution | 360*720dpi、720*720dpi、720*1080dpi、720*1440dpi | |||||||

| Printhead height | 120mm | |||||||

| Printing Size | 2500mm*1300mm | |||||||

| Print speed | Ink Color | CMYK+LC+LM+W+V | (CMYK+LC+LM+W)*2 | |||||

| Draft | 17㎡/h | 34㎡/h | ||||||

| Production | 15㎡/h | 30㎡/h | ||||||

| Precision | 12㎡/h | 24㎡/h | ||||||

| Ink | Ink Tank Capacity | 3000ml Per Color | ||||||

| Supply System | Positive-Pressure CISS | |||||||

| Curing Method | LED UV Curable | |||||||

| RIP Software | Photoprint,Onyx(Option) | |||||||

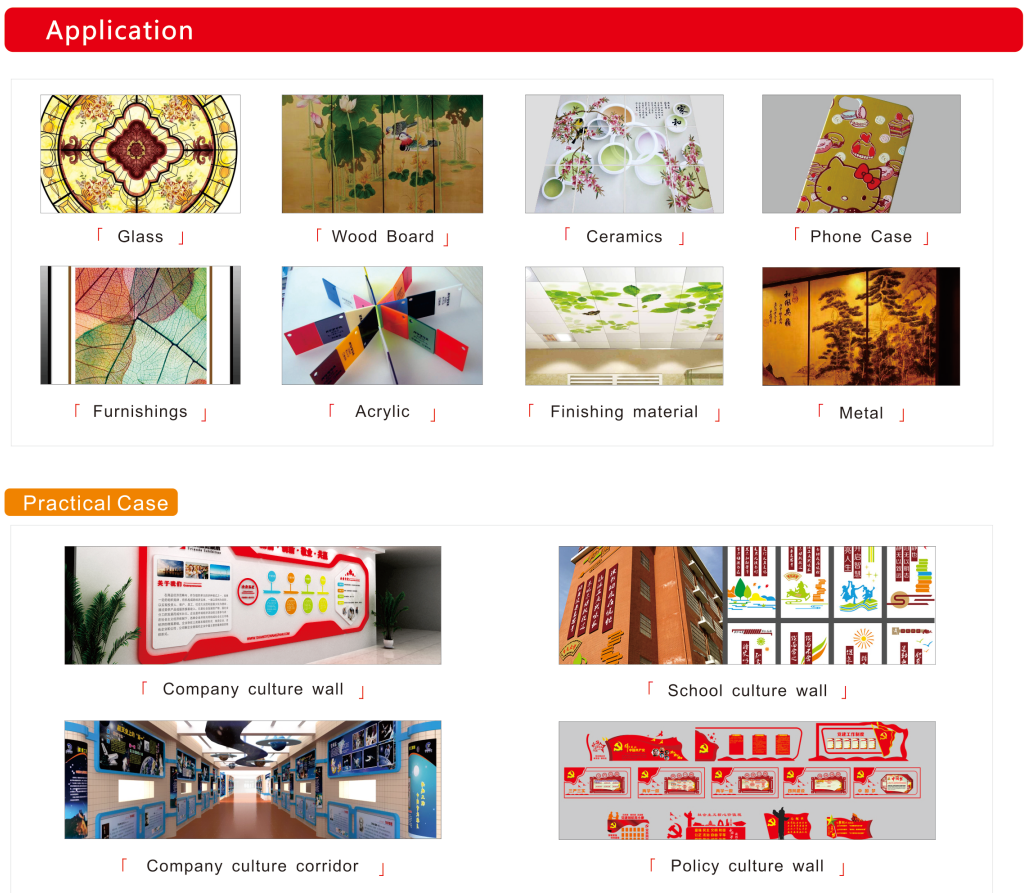

| Media | Glass,Aluminium-plastic panel,foam board,Wood,Acrylic,Ceramics,Metal,Plastic,PVC,Textile,Wallpaper,Stone etc. | |||||||

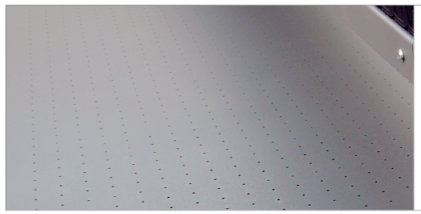

| Platform | With sucking function and Locating for media | |||||||

| Power Input | 220-240V,50/60HZ,32A | |||||||

| Work Environment | Temperature:20-28℃ | |||||||

| Humidity:40-70% | ||||||||

| Interface | USB 2.0 | |||||||

| Language | Chinese/English | |||||||

| OS | Windows 7 64bit | |||||||

| File Format | JPG/TIFF/PDF/PSD etc | |||||||

| Machine Power | 4000W | |||||||

| Machine size(LxWxH) | 4500mm*2200mm*1500mm(L*W*H) | |||||||

| Packing size(LxWxH) | 4600mm*2300mm*1700mm(L*W*H) | |||||||

| G.W(kg) | 1600kg | |||||||

| N.W(kg) | 1500kg | |||||||

![TT$F~PX$N}E]77MO`7D`IV0.png TT$F~PX$N}E]77MO`7D`IV0.png](/upfile/201903/2019031840619673.png)

![42P@D9I])BG))TI%1M]HM_P.png 42P@D9I])BG))TI%1M]HM_P.png](/upfile/201903/2019031840259953.png) | 1. Main frame is made of steel and processed in fire(32 points for adjusting level).Leveling precision within 1mm.European standard joint, more stable,without deformation after long time using; |

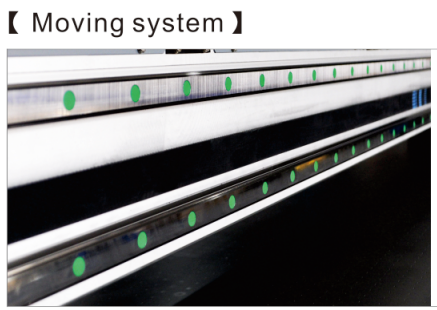

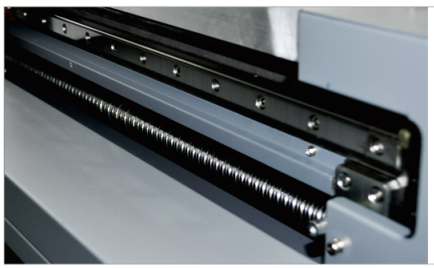

| 2. X axis moving:Double guide reails to keep precision of carriage moving; |

| 3. Y axis moving:Guide rail+lead screw moving system,kept the stationarity of beam moving. |

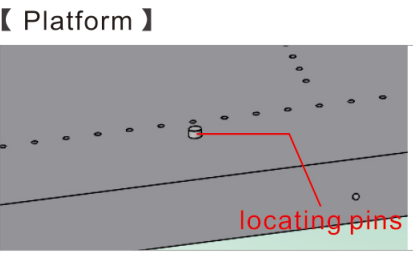

| 4. Locating pin:There are locating pins on the platform to fix media more convenient. |

| 5. Sucking system on the platform: Sucking platform was divided into 4 parts, that could be controlled one by one. |

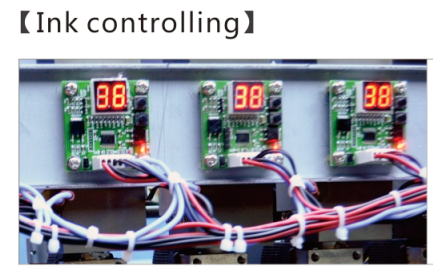

| 6. Ink temperature controlling system: Ink temperature could be controlled as requirements. |

| 7. Magnetic valve controlling system: Smart magnetic vavle automatically working to control ink drop from subtank. |

| 8. Smart warning system for lacking of inks:When lacking of inks in ink box, led light flash and give a alarm warning. |

| 9.White ink stirring:In white ink box, there is a stirring rod automatically working to avoid ink precipitate. |

- previous:暂无信息

- next: Locor A3 UV Flatbed Printer with 2 XP600 Printheads desktop printer