How to Keep UV Flatbed Prints Color Away from Fading

We know that the main factors causing the fading of the print pattern are air, light and heat, because there is oxygen in the air, and the ink will oxidize and have a great influence on the color of the pattern. There are a number of reasons why the print pattern fades, and the first and most influential is the printing material. If the printing material is softer, the voids between the particles are large, and the surface in contact with the air is very large, it will be easy to fade. If it is a smooth and hard surface material, it is not easy to fade under normal circumstances, but if placed in the sun exposure, it will also fade

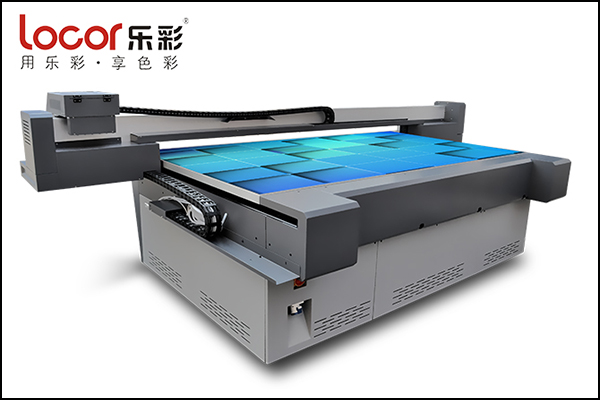

UV flatbed printer can meet the metal, glass, leather, ceramics, wood, cloth, PVC, acrylic, advertising materials and other industries of high-quality high-demand printing needs. When you print a pattern using a UV printer, customers may be concerned about fading problems and wondering how long the pattern can be maintained.

How to keep the UV flatbed printing pattern does not fade? The best way to maintain the durability of the UV printer print pattern is to use the right ink and do a good post-protection treatment after printing is complete. But it can fade when exposed to ultraviolet light and ordinary incandescent lamps. So want to maintain a long-term UV flatbed printing pattern does not fade to do the following two points:

1, the use of good sealing ink, which is to ensure that the pattern of long-term non-fading basic conditions. Do not choose the long shelf life of the ink, because its particles are larger, the interior is not easy to oxidize, will destroy the UV printer printing effect.

2, the printed pattern placed in a cool without strong light, to ensure that the pattern is not exposed to strong light.